In-depth break down of BoilingUpdated 2 days ago

Boiling your wort isn’t just a routine step—it plays a key role in the chemical and physical transformations that define your beer’s flavor, stability, and clarity. This article explains how boil time and boil processes impact your final brew.

Why Boil the Wort?

Boiling initiates multiple processes critical to beer quality:

Wort Sterilization

Boiling at 100°C (212°F at sea level) kills spoilage organisms, such as Lactobacillus and Pediococcus, as well as wild yeasts like Brettanomyces. Combined with the wort’s low pH and antibacterial hop compounds, this prevents the formation of acid, haze, and off-flavors caused by microbial activity.

Enzyme Inactivation

While most enzymes are already deactivated during mash-out, boiling ensures any remaining ones are stopped. This prevents further conversion of unfermentable sugars into fermentable sugars, preserving the desired sugar profile.

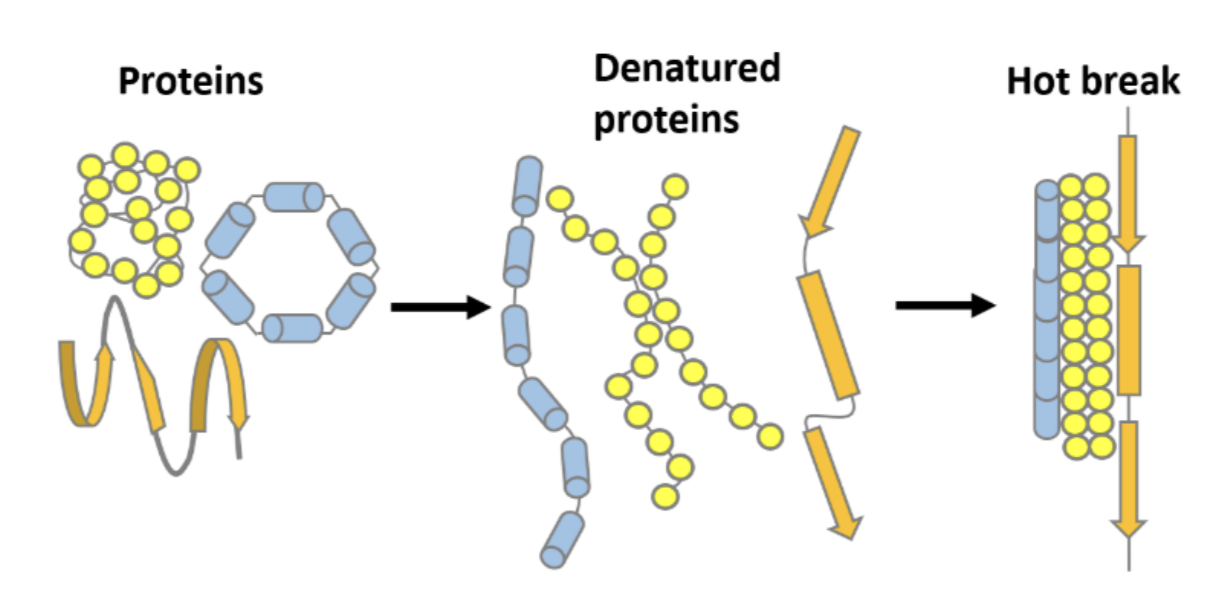

Hot Break Formation

Proteins from the malt and polyphenols from grains and hops precipitate when heated. This hot break improves clarity and fermentation performance. Vigorous boiling, low pH, and longer boil times enhance this protein coagulation. If not removed, excess proteins can:

Inhibit fermentation by sticking to yeast cells

Create haze in the final beer

Evaporation of Water

About 2.5% of wort volume is evaporated during a 60-minute boil in Exobrew (less than the 8–12% in commercial systems). This concentrates the wort and raises gravity. Expect a pre-boil gravity that is 3–4 points lower than the post-boil gravity.

Removal of Undesired Volatiles

Volatiles like dimethyl sulphide (DMS)—which smells like cooked corn—are produced when S-methyl-methionine (SMM) breaks down in heat. Boiling allows these compounds to evaporate, especially in beers made with pale malts (like Pilsner or Pale Ale). Proper boiling is crucial for reducing DMS.

Formation of Aromatic and Colouring Compounds

The Maillard reaction, which occurs between amino acids and reducing sugars, creates deep-flavored and colored compounds like melanoidins. These add maltiness, depth, and hue—particularly in darker beers or those with longer boils.

Ingredient Additions

Boiling is also the stage at which hops and other ingredients are added to impart bitterness, flavor, and aroma. Hop alpha acids are isomerized during the boiling process, producing bitterness. (See our article Ingredients in Boiling for more.)

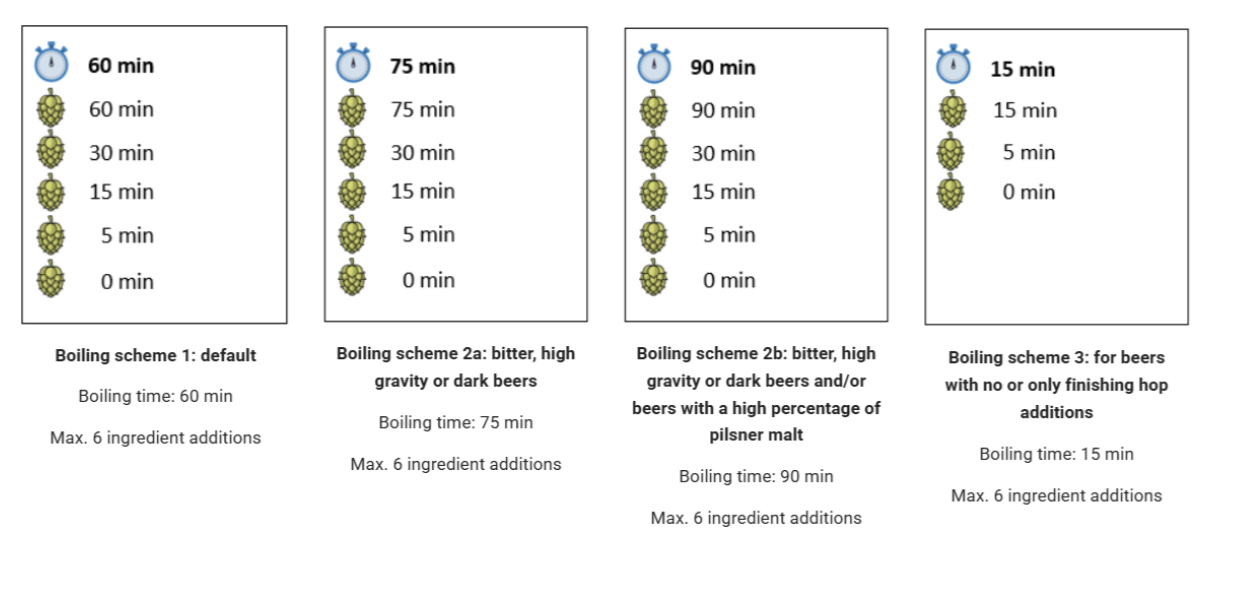

Choosing the Right Boil Time

Minimum Boil: 15 Minutes

Use when no hops or only 0-minute aroma hops are added.

Sufficient for enzyme inactivation and sterilization

Minimal evaporation and bitterness

Standard Boil: 60 Minutes

Most commonly used duration in craft brewing

Ensures complete hop isomerization for bitterness

Adequate volatile removal and protein coagulation

Balanced for color and flavor development

Works well for most beer styles

Extended Boil: 90+ Minutes

Increases evaporation, concentrating sugars and color

Produces deeper flavors and richer mouthfeel

Ideal for high-gravity beers like barleywines, strong ales, or imperial stouts

Enhances bitterness if hops are added early in the boil

What Does Boil Time Affect?

| Factor | Short Boil (15–30 min) | Long Boil (60–90+ min) |

|---|---|---|

| Bitterness | Low (less hop isomerization) | High (more bitterness extraction) |

| Color | Light | Darker due to Maillard reactions |

| Volatile Removal | Moderate | High – removes DMS and other compounds |

| Aroma Preservation | High (if no early hops are used) | Lower (aromas can boil off with long exposure) |

| Clarity | Moderate protein coagulation | Strong hot break and better clarity |

| Head Retention | Slightly better | May decrease with very long boils |

Style-Specific Guidelines

New England IPA:

Shorter boil (15–30 min), with hop additions at 0 min or whirlpool only. Emphasizes aroma and low bitterness.Classic Ales & Lagers:

Standard 60-minute boil. Balanced flavor, clarity, and bitterness.Imperial Stout / Barleywine:

90-minute (or longer) boil for deeper color, more body, and concentrated flavor.

Summary

Boil duration is one of the key tools you have to shape your beer’s final profile. While 60 minutes is a safe and effective standard, adjusting your boil time gives you control over flavor depth, bitterness, color, and aroma expression.

Want to go further? Try combining boil time adjustments with strategic hop scheduling for even more control.