Mashing process - in depth overviewUpdated a day ago

Brief summary of mashing

What is malt?

When referred to malt this means a grain that has been malted. Malting is a process that enhances the enzyme creation inside the grain.

Without these enzymes it is impossible to break down the starch and protein inside a grain and all that will be left after mashing is a starchy, cloudy water.

For a good mashing process the malted grains have to be crushed first, so the enzymes have easier access to the available starch inside the grain.

The mashing process is impacted most by 4 important factors:

1) Type of (malted) grain used;

2) Temperature;

3) Time;

4) Acidity (pH).

Factor 1 - Grain (type)

This means that the type of grain used can be a big influence to the outcome of the beer.

In brewing there are different types of grain, malted and unmalted:

1) Base malt - forms the biggest part of the grain bill due to its enzymatic power and high yield.

2) Specialty malts - smaller part of the grain bill and mostly used for extra flavour and colour of the beer. The darker the malt, the less enzymatic power.

3) Flaked grains - smaller part of the grain bill and mostly used for the creation of more body and a richer foam. Base malt Specialty malt Flaked malt Base malt is always required because the other malt types lack the enzymatic power to convert the available starch into soluable sugars. Without this malt, the alcohol amount in the beer will be heavily reduced.

Base malt Specialty malt Flaked malt Base malt is always required because the other malt types lack the enzymatic power to convert the available starch into soluable sugars. Without this malt, the alcohol amount in the beer will be heavily reduced.

Factor 2 - Temperature

Temperature is the key factor during the mashing process.

Malt contains enzymes, which can breakdown carbohydrates and proteins. These enzymes are (most) active at specific temperatures.

A starch (amylose) enzyme is called 'amylase', a protein enzyme is called 'protease'.

Amylase

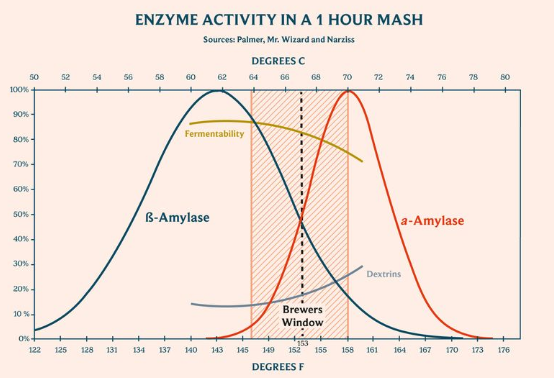

The most important amylase enzymes inside malt are alpha-amylase and beta-amylase.

Beta-amylase is the biggest contributor to fermentable (soluable) sugars and is (most) active between 60-65°C (140-149F). This will yield the highest alcohol potential due to the high fermentability of these sugars.

Alpha-amylase also contributes to fermentable sugars, but creates unfermentable dextrins.These dextrins are a big contributor to the body of the beer. It is (most) active between 68-72°C (155-160F).

If the temperatures are not met, these enzymes will be much less active and have a poorer performance.

In practice a lot of recipes perform mashing at 66°C, because both enzymes will be active and create a standard composition of fermentable and unfermentable sugars. Amylase enzyme activity

Amylase enzyme activity

Protease

During the mashing different protease enzymes are active. The most important one is beta-glucanase. It breaks down beta-glucans (proteins that could cause a haze in the beer if not broken down).

This enzyme is most active at 43°C (119F) and this part of the mashin is often referred to as the 'protein rest'.

Nowadays many malts have been refined so well that the protein rest is often not needed anymore, because it already happened during the malting process.

Factor 3 - Time

Time is another important factor during the mashing process and goes hand in hand with the types of grains that are used.

If the grain bill consists fully out of malts with a high enzymatic power, the mash can be shorter than normal. It works both ways, so the less enzymatic power in the grain bill, the longer the mash for a complete conversion.

Typically most of the starch is converted within 60 minutes of mashing at 67°C (where both amylase enzymes are active).

Mashing times usually vary between 60-90 minutes, where the 90 minute duration often consists out of a multiple step mashing scheme.

Multistep mash

Multistep mash

As can be seen above, the first 3 steps are performed at lower temperatures, mostly activating the protelitic enzymes.

Then the temperature ramps up and the sacharification (conversion from starch to sugar) is at its most efficient.

Most mashing schemes will start from the 55C step and skip the first 2, unless alot of proteins have to be dealt with.

Factor 4 - Acidity (pH)

The mashing process and the efficiency of the enzymes gets affected by the acidity of the liquid, referred to as pH. For this specific reason most brewers treat their water or malt mixture with lactic acid to bring the pH down, making it more acidic.

Beta-amylase is most efficient between a pH of 5.1-5.3 and alpha-amylase between 5.3-5.7, making a pH of 5.3 ideal.

Even without lowering the pH the enzymes are still active at higher levels.