The Four Key Factors of MashingUpdated 2 days ago

The Four Key Factors of Mashing

Grain Type

Base Malts: Make up most of the grist; full of enzymes and give high sugar yield.

Specialty Malts: Add color and flavor; darker malts have fewer enzymes.

Flaked Grains: Boost body and head retention but need base malt to convert starch.

Base malt , Specialty malt Flaked malt

2. Temperature

Enzyme Activity:

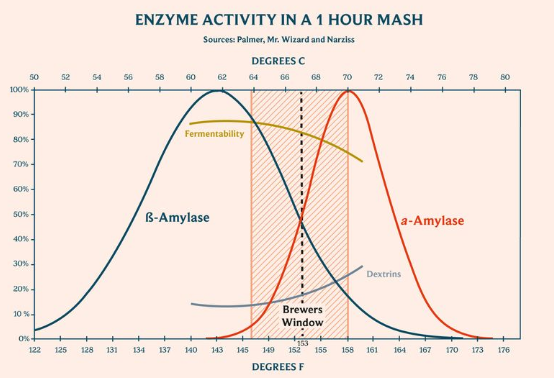

Beta-amylase (140–149 °F / 60–65 °C): Makes simple, fermentable sugars → drier, higher‐ABV beer.

Alpha-amylase (155–160 °F / 68–71 °C): Makes unfermentable dextrins → fuller body, more mouthfeel.

Common Mash Temp: Around 152 °F / 67 °C for a balanced mix of both enzymes.

Amylase enzyme activity

Amylase enzyme activity

3. Time

Typical Range: 60–90 minutes.

Shorter Mash: If your grain bill is mostly base malt (high enzyme power).

Longer or Step Mash: If you use many specialty grains or want more precise control.

4. Acidity (pH)

Ideal Range: pH 5.2–5.4.

Why:

Beta-amylase works best at pH 5.1–5.3.

Alpha-amylase works best at pH 5.3–5.7.

Tip: Adjust with food-grade acids or brewing salts if needed.